SHT11 데이터 시트보기 (PDF) - Unspecified

부품명

상세내역

제조사

SHT11 Datasheet PDF : 9 Pages

| |||

SHT1x / SHT7x Relative Humidity & Temperature Sensor System

4 Applications Information

4.1 Operating and Storage Conditions

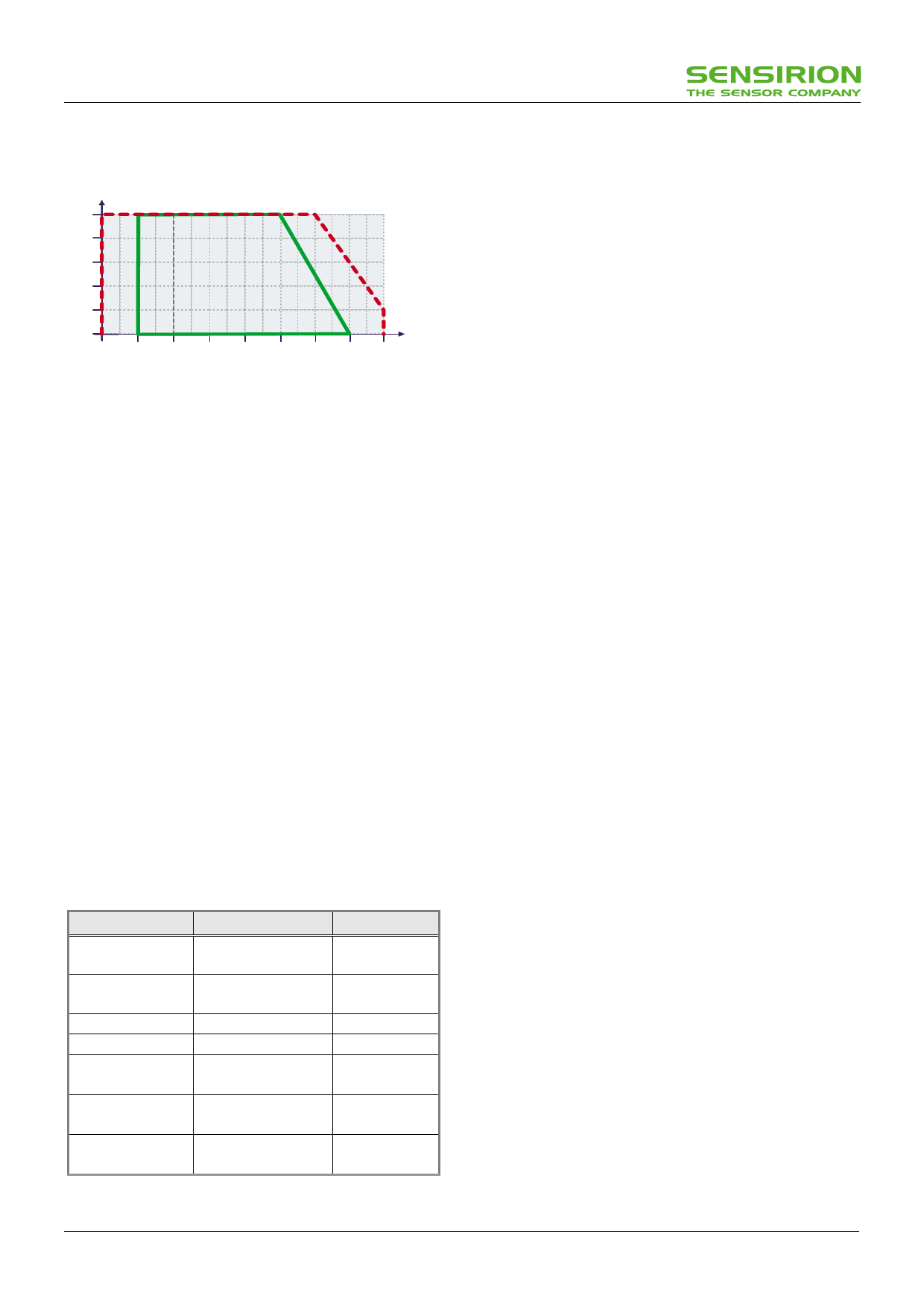

[%RH]

100

80

Maximum operating

conditions

60

Normal operating

40

conditions

20

0

[°C]

-40 -20 0 20 40 60 80 100 120

Figure 11 Recommended operating conditions

Conditions outside the recommended range may temporarily

offset the RH signal up to ±3 %RH. After return to normal

conditions it will slowly return towards calibration state by

itself. See 4.3 “Reconditioning Procedure” to accelerate this

process. Prolonged exposure to extreme conditions may

accelerate ageing.

4.2 Exposure to Chemicals

Vapors may interfere with the polymer layers used for

capacitive humidity sensors. The diffusion of chemicals into

the polymer may cause a shift in both offset and sensitivity.

In a clean environment the contaminants will slowly outgas.

The reconditioning procedure described below will

accelerate this process.

High levels of pollutants may cause permanent damage to

the sensing polymer.

4.3 Reconditioning Procedure

The following reconditioning procedure will bring the sensor

back to calibration state after exposure to extreme conditions

or chemical vapors.

80-90 °C (176-194°F) at < 5 %RH for 24h (baking) followed by

20-30 °C (70-90°F) at > 74 %RH for 48h (re-hydration)

4.4 Qualifications

Extensive tests were performed in various environments.

Please contact SENSIRION for additional information.

Environment

Norm

Results(1)

Temperature

Cycles

JESD22-A104-B -40 °C Within

/ 125°C, 1000cy

Specifications

HAST

JESD22-A110-B

Reversible shift

Pressure Cooker 2.3bar 125°C 85%RH by +2 %RH

Salt Atmosphere DIN-50021ss

Within Spec.

Condensing Air -

Within Spec.

Freezing cycles -20 / +90°C, 100cy

fully submerged 30min dwell time

Reversible shift

by +2 %RH

Various Automotive DIN 72300-5

Chemicals

Within

Specifications

Cigarette smoke Equivalent to 15years Within

in a mid-size car

Specifications

Table 9 Qualification tests (excerpt)

4.5 ESD (Electrostatic Discharge)

ESD immunity is qualified according to MIL STD 883E,

method 3015 (Human Body Model at ±2 kV)).

Latch-up immunity is provided at a force current of ±100 mA

with Tamb = 80 °C according to JEDEC 17.

See application note “ESD, Latchup and EMC” for more

information.

4.6 Temperature Effects

The relative humidity of a gas strongly depends on its

temperature. It is therefore essential to keep humidity

sensors at the same temperature as the air of which the

relative humidity is to be measured.

If the SHTxx shares a PCB with electronic components that

give off heat it should be mounted far away and below the

heat source and the housing must remain well ventilated.

To reduce heat conduction copper layers between the

SHT1x and the rest of the PCB should be minimized and a

slit may be milled in between. ( See figure 14 )

4.7 Materials Used for Sealing / Mounting

Many materials absorb humidity and will act as a buffer,

increasing response times and hysteresis. Materials in the

vicinity of the sensor must therefore be carefully chosen.

Recommended materials are:

All Metals, LCP, POM (Delrin), PTFE (Teflon), PE, PEEK,

PP, PB, PPS, PSU, PVDF, PVF

For sealing and gluing (use sparingly):

High filled epoxy for electronic packaging (e.g. glob top,

underfill), and Silicone are recommended.

4.8 Membranes

A membrane can be used to prevent dirt from entering the

housing and to protect the sensor. It will also reduce peak

concentrations of chemical vapors. For optimal response

times air volume behind the membrane must be kept to a

minimum.

4.9 Light

The SHTxx is not light sensitive. Prolonged direct exposure

to sunshine or strong UV radiation may age the housing.

4.10 Wiring Considerations and Signal Integrity

Carrying the SCK and DATA signal parallel and in close

proximity (e.g. in wires) for more than 10cm may result in

cross talk and loss of communication. This may be resolved

by routing VDD and/or GND between the two data signals.

Please see the application note “ESD, Latchup and EMC” for

more information.

Power supply pins (VDD, GND) should be decoupled with a

100 nF capacitor if wires are used.

(1) The temperature sensor passed all tests without any detectable drift. Package and electronics also passed 100%

www.sensirion.com

v2.01 March 2003

6/9