AP1507(2007) 데이터 시트보기 (PDF) - Diodes Incorporated.

부품명

상세내역

제조사

AP1507 Datasheet PDF : 10 Pages

| |||

AP1507

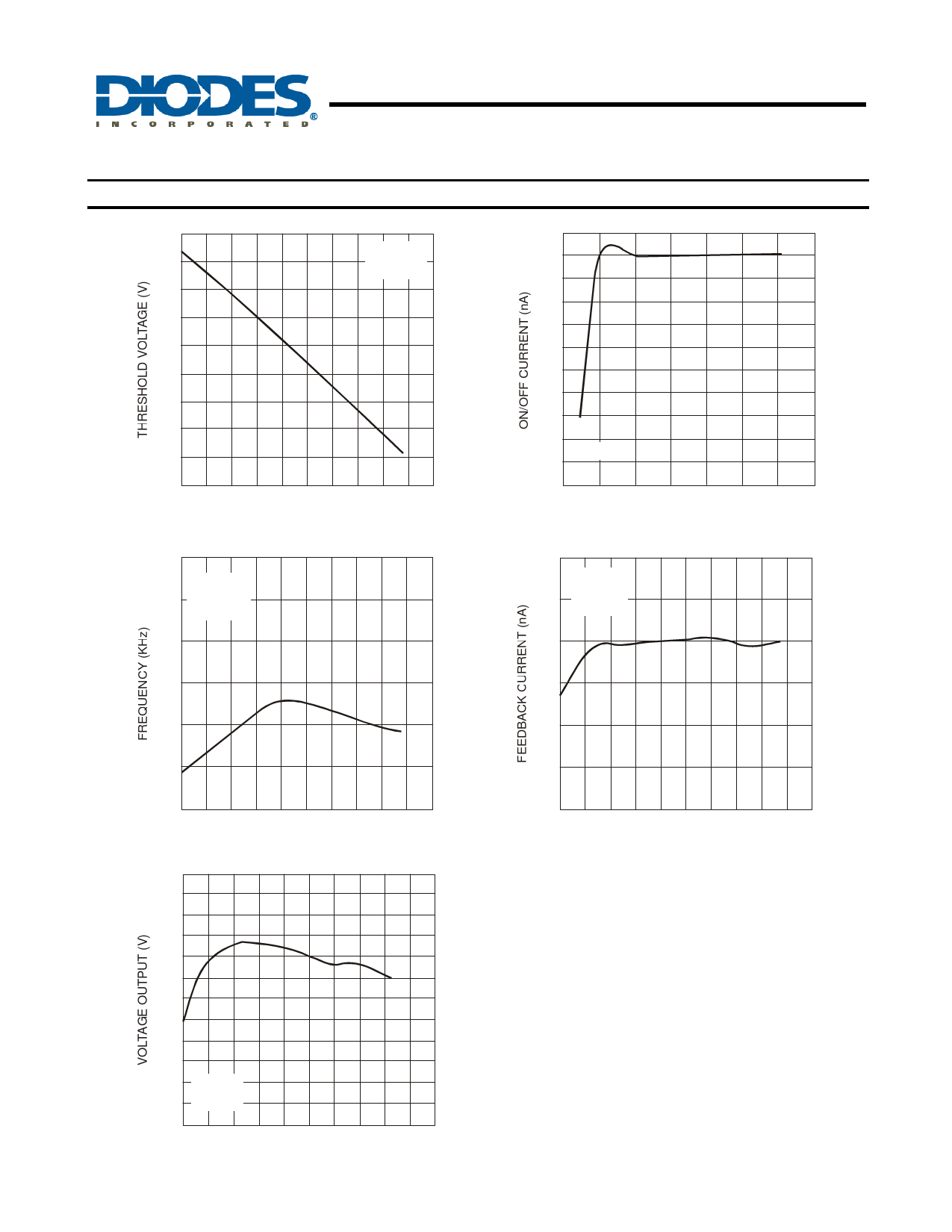

150KHz, 3A PWM BUCK DC/DC CONVERTER

Applications Information

Pin Functions

+VIN

This is the positive input supply for the IC switching regulator. A

suitable input bypass capacitor must be present at this pin to

minimize voltage transients and to supply the switching currents

needed by the regulator.

Ground

Circuit ground.

Output

Internal switch. The voltage at this pin switches between (+VIN –

VSAT) and approximately – 0.5V, with a duty cycle of

approximately VOUT / VIN. To minimize coupling to sensitive

circuitry, the PC board copper area connected to this pin should

be kept at a minimum.

Feedback (FB)

Senses the regulated output voltage to complete the feedback

loop.

ON /OFF (SD)

Allows the switching regulator circuit to be shutdown using logic

level signals thus dropping the total input supply current to

approximately 150uA. Pulling this pin below a threshold voltage

of approximately 1.3V turns the regulator on, and pulling this pin

above 1.3V (up to a maximum of 18V) shuts the regulator down.

If this shutdown feature is not needed, the ON /OFF pin can be

wired to the ground pin.

Thermal Considerations

The TO-252 surface mount package tab is designed to be

soldered to the copper on a printed circuit board. The copper

and the board are the heat sink for this package and the other

heat producing components, such as the catch diode and

inductor. The PC board copper area that the package is soldered

to should be at least 0.8 in2, and ideally should have 2 or more

square inches of 2 oz. additional copper area which improves the

thermal characteristics. With copper areas greater than

approximately 6 in2, only small improvements in heat dissipation

are realized. If further thermal improvements are needed, double

sided, multi-layer PC board with large copper areas and/or airflow

will be recommended.

The AP1507 (TO-252 package) junction temperature rises above

ambient temperature with a 3A load for various input and output

voltages. This data was taken with the circuit operating as a

buck-switching regulator with all components mounted on a PC

board to simulate the junction temperature under actual operating

conditions. This curve can be used for a quick check for the

approximate junction temperature for various conditions, but

there are many factors that can affect the junction temperature.

When load currents higher than 3A are used, double sided or

multi-layer PC boards with large copper areas and/or airflow

might be needed, especially for high ambient temperatures and

high output voltages.

For the best thermal performance, wide copper traces and

generous amounts of printed circuit board copper should be used

in the board layout. (One exception to this is the output (switch)

pin, which should not have large areas of copper.) Large areas

of copper provide the best transfer of heat (lower thermal

resistance) to the surrounding air, and moving air lowers the

thermal resistance even further.

Package thermal resistance and junction temperature rise

numbers are all approximate, and there are many factors that will

affect these numbers. Some of these factors include board size,

shape, thickness, position, location, and even board temperature.

Other factors are trace width, total printed circuit copper area,

copper thickness, single or double-sided, multi-layer board and

the amount of solder on the board. The effectiveness of the PC

board to dissipate heat also depends on the size, quantity and

spacing of other components on the board, as well as whether

the surrounding air is still or moving. Furthermore, some of these

components such as the catch diode will add heat to the PC

board and the heat can vary as the input voltage changes. For

the inductor, depending on the physical size, type of core

material and the DC resistance, it could either act as a heat sink

taking heat away from the board, or it could add heat to the

board.

AP1507 Rev. 1

8 of 10

www.diodes.com

FEBRUARY 2007

© Diodes Incorporated