LT1956-5 데이터 시트보기 (PDF) - Linear Technology

부품명

상세내역

제조사

LT1956-5 Datasheet PDF : 28 Pages

| |||

LT1956/LT1956-5

APPLICATIO S I FOR ATIO

Peak-to-peak output ripple voltage is the sum of a triwave

(created by peak-to-peak ripple current (ILP-P) times ESR)

and a square wave (created by parasitic inductance (ESL)

and ripple current slew rate). Capacitive reactance is

assumed to be small compared to ESR or ESL.

VRIPPLE

=

(ILP-P

)(ESR)

+

(ESL)Σ

dI

dt

where:

ESR = equivalent series resistance of the output

capacitor

ESL = equivalent series inductance of the output

capacitor

dI/dt = slew rate of inductor ripple current = VIN/L

Peak-to-peak ripple current (ILP-P) through the inductor

and into the output capacitor is typically chosen to be

between 20% and 40% of the maximum load current. It is

approximated by:

ILP-P

=

(VOUT )(VIN – VOUT

(VIN)(f)(L)

)

Example: with VIN = 12V, VOUT = 5V, L = 15µH, ESR =

0.080Ω and ESL = 10nH, output ripple voltage can be

approximated as follows:

( )( ) ILP-P

=

(12)

15

(5)(12

• 10–6

− 5)

500

•

10–6

= 0.389A

Σ

dI

dt

=

15

12

• 10−6

=

106

• 0.8

( )( ) VRIPPLE = (0.389)(0.08) + 10 • 10−9 106 (0.8)

= 0.031+ 0.008 = 39mVP-P

To reduce output ripple voltage further requires an in-

crease in the inductor value with the trade-off being a

physically larger inductor with the possibility of increased

component height and cost.

Ceramic Output Capacitor

An alternative way to further reduce output ripple voltage

is to reduce the ESR of the output capacitor by using a

10

ceramic capacitor. Although this reduction of ESR re-

moves a useful zero in the overall loop response, this zero

can be replaced by inserting a resistor (RC) in series with

the VC pin and the compensation capacitor CC. (See

Ceramic Capacitors in Applications Information.)

Peak Inductor Current and Fault Current

To ensure that the inductor will not saturate, the peak in-

ductor current should be calculated knowing the maximum

load current. An appropriate inductor should then be cho-

sen. In addition, a decision should be made whether or not

the inductor must withstand continuous fault conditions.

If maximum load current is 0.5A, for instance, a 0.5A

inductor may not survive a continuous 2A overload condi-

tion. Dead shorts will actually be more gentle on the

inductor because the LT1956 has frequency and current

limit foldback.

Peak inductor and switch current can be significantly

higher than output current, especially with smaller induc-

tors and lighter loads, so don’t omit this step. Powdered

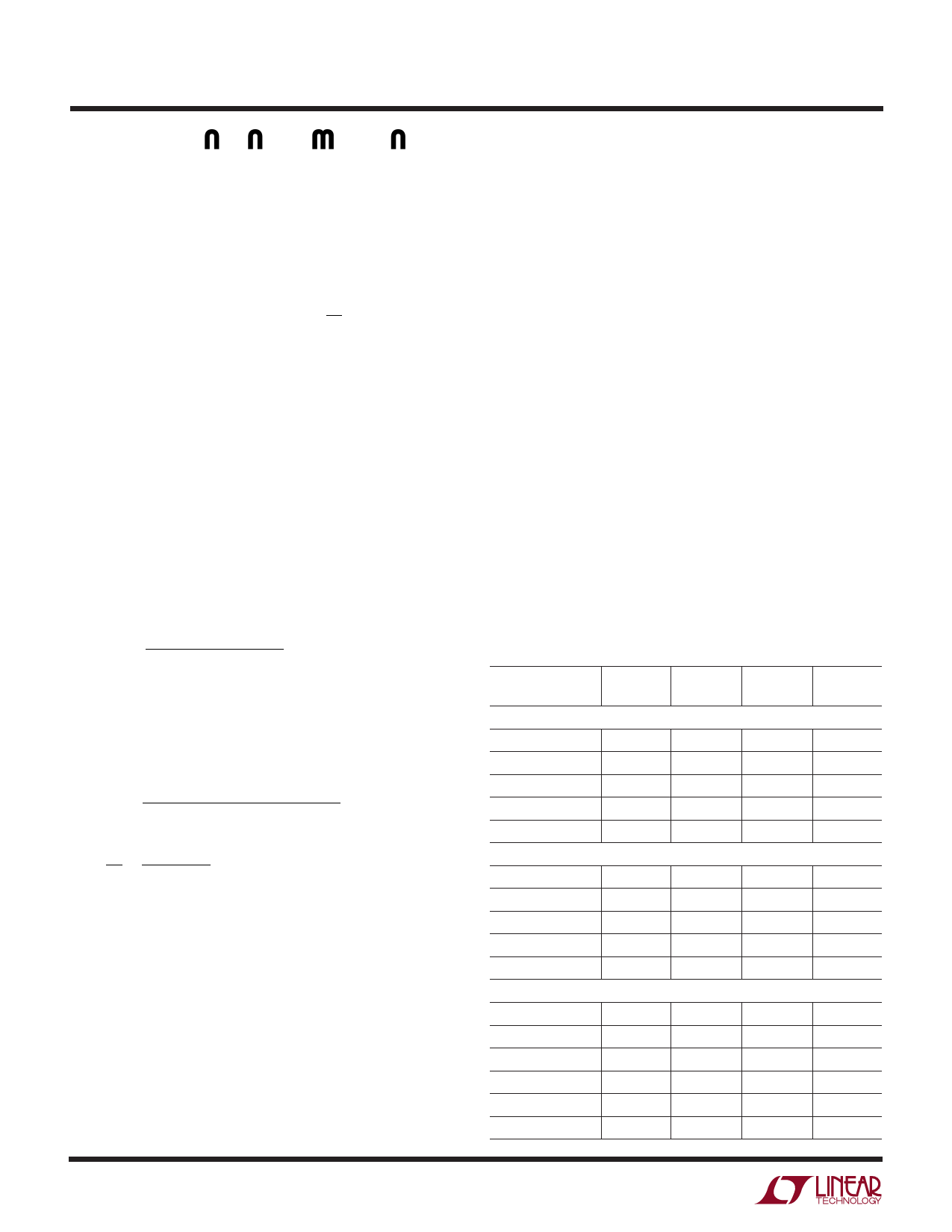

Table 2

VENDOR/

PART NO.

Coiltronics

UP1B-100

UP1B-220

UP2B-220

UP2B-330

UP1B-150

Coilcraft

D01813P-153HC

D01813P-103HC

D53316P-223

D53316P-333

LP025060B-682

Sumida

CDRH4D28-4R7

CDRH5D28-100

CDRH6D28-150

CDRH6D28-180

CDRH6D28-220

CDRH6D38-220

VALUE

(µH)

IDC(MAX)

(Amps)

DCR

(Ohms)

HEIGHT

(mm)

10

1.9

0.111

5.0

22

1.2

0.254

5.0

22

2.0

0.062

6.0

33

1.7

0.092

6.0

15

1.5

0.175

5.0

15

1.5

0.170

5.0

10

1.9

0.111

5.0

22

1.6

0.207

5.1

33

1.4

0.334

5.1

6.8

1.3

0.165

1.65

4.7

1.32

0.072

3.0

10

1.30

0.065

3.0

15

1.40

0.084

3.0

18

1.32

0.095

3.0

22

1.20

0.128

3.0

22

1.30

0.096

4.0

1956f