RT8256 데이터 시트보기 (PDF) - Richtek Technology

부품명

상세내역

제조사

RT8256 Datasheet PDF : 12 Pages

| |||

RT8256

Application Information

The RT8256 is an asynchronous high voltage buck

converter that can support the input voltage range from

4.75V to 22V and the output current can be up to 2A.

Output Voltage Setting

The resistive divider allows the FB pin to sense the output

voltage as shown in Figure 1.

VOUT

R1

FB

RT8256

R2

GND

Figure 1. Output Voltage Setting

The output voltage is set by an external resistive divider

according to the following equation :

VOUT

=

VFB

⎛⎜⎝1+

R1

R2

⎞⎟⎠

Where VFB is the feedback reference voltage (1.222V typ.).

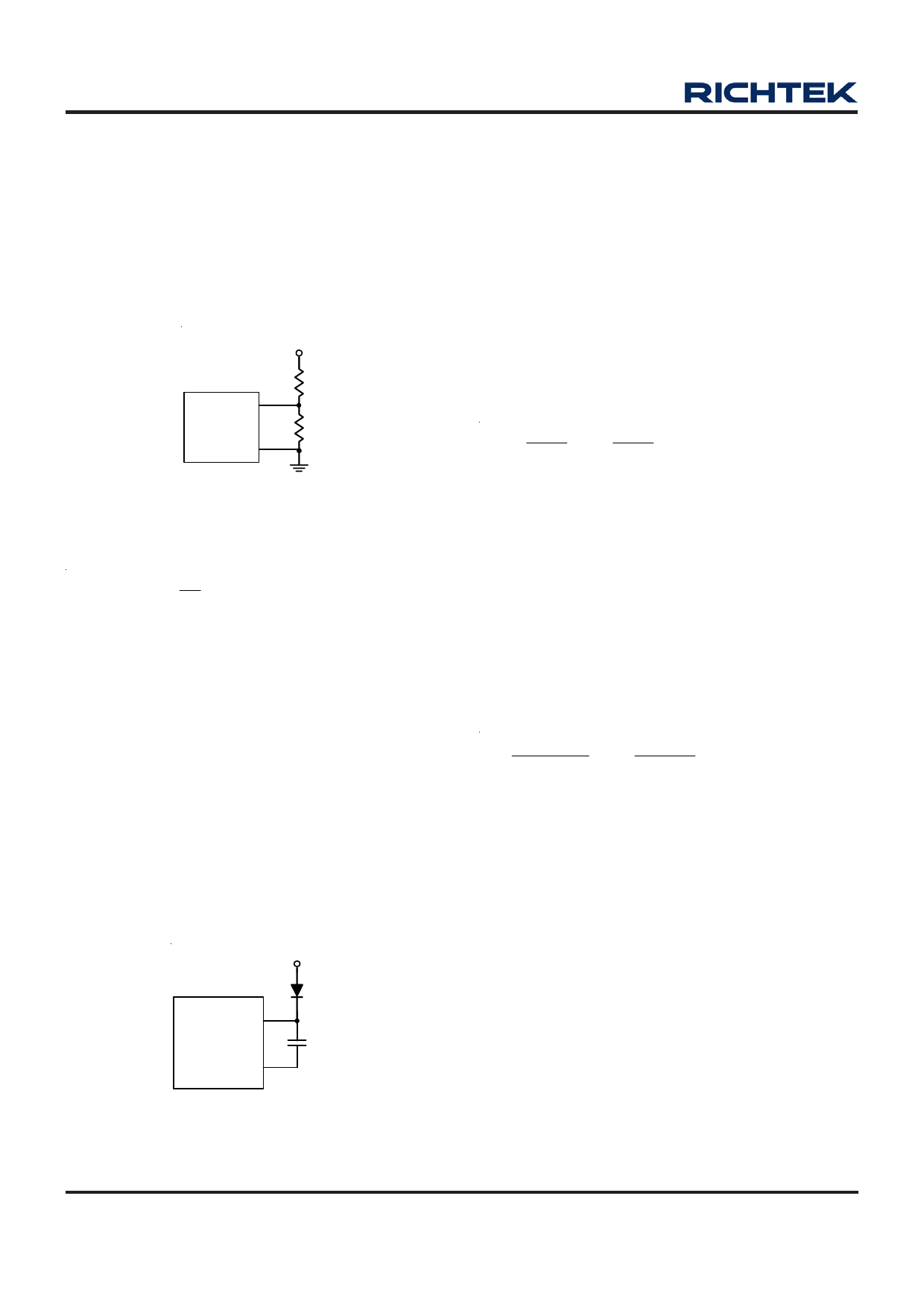

External Bootstrap Diode

Connect a 10nF low ESR ceramic capacitor between the

BOOT pin and SW pin. This capacitor provides the gate

driver voltage for the high side MOSFET.

It is recommended to add an external bootstrap diode

between an external 5V and the BOOT pin for efficiency

improvement when input voltage is lower than 5.5V or duty

ratio is higher than 65%. The bootstrap diode can be a

low cost one such as 1N4148 or BAT54.

The external 5V can be a 5V fixed input from system or a

5V output of the RT8256.

5V

BOOT

RT8256

SW

10nF

Figure 2. External Bootstrap Diode

Soft-Start

The RT8256 contains an internal soft-start clamp that

gradually raises the output voltage. The soft-start time is

designed by the internal capacitor. The typical soft-start

time is 2ms.

Inductor Selection

The inductor value and operating frequency determine the

ripple current according to a specific input and output

voltage. The ripple current ΔIL increases with higher VIN

and decreases with higher inductance.

ΔIL

=

⎡

⎢⎣

VOUT

f ×L

⎤

⎥⎦

×

⎡⎢⎣1−

VOUT

VIN

⎤

⎥⎦

Having a lower ripple current reduces not only the ESR

losses in the output capacitors but also the output voltage

ripple. High frequency with small ripple current can achieve

highest efficiency operation. However, it requires a large

inductor to achieve this goal.

For the ripple current selection, the value of ΔIL = 0.4(IMAX)

will be a reasonable starting point. The largest ripple

current occurs at the highest VIN. To guarantee that the

ripple current stays below the specified maximum, the

inductor value should be chosen according to the following

equation :

L

=

⎡

⎢⎣

f

×

VOUT

ΔIL(MAX)

⎤

⎥⎦

×

⎡⎢⎣1−

VOUT

VIN(MAX)

⎤

⎥⎦

Inductor Core Selection

The inductor type must be selected once the value for L

is known. Generally speaking, high efficiency converters

can not afford the core loss found in low cost powdered

iron cores. So, the more expensive ferrite or

mollypermalloy cores will be a better choice.

The selected inductance rather than the core size for a

fixed inductor value is the key for actual core loss. As the

inductance increases, core losses decrease. Unfortunately,

increase of the inductance requires more turns of wire

and therefore the copper losses will increase.

Ferrite designs are preferred at high switching frequency

due to the characteristics of very low core losses. So,

design goals can focus on the reduction of copper loss

and the saturation prevention.

www.richtek.com

8

DS8256-01 March 2011