TDA4857 데이터 시트보기 (PDF) - Philips Electronics

부품명

상세내역

제조사

TDA4857 Datasheet PDF : 56 Pages

| |||

Philips Semiconductors

I2C-bus autosync deflection controller for

PC monitors

Product specification

TDA4857PS

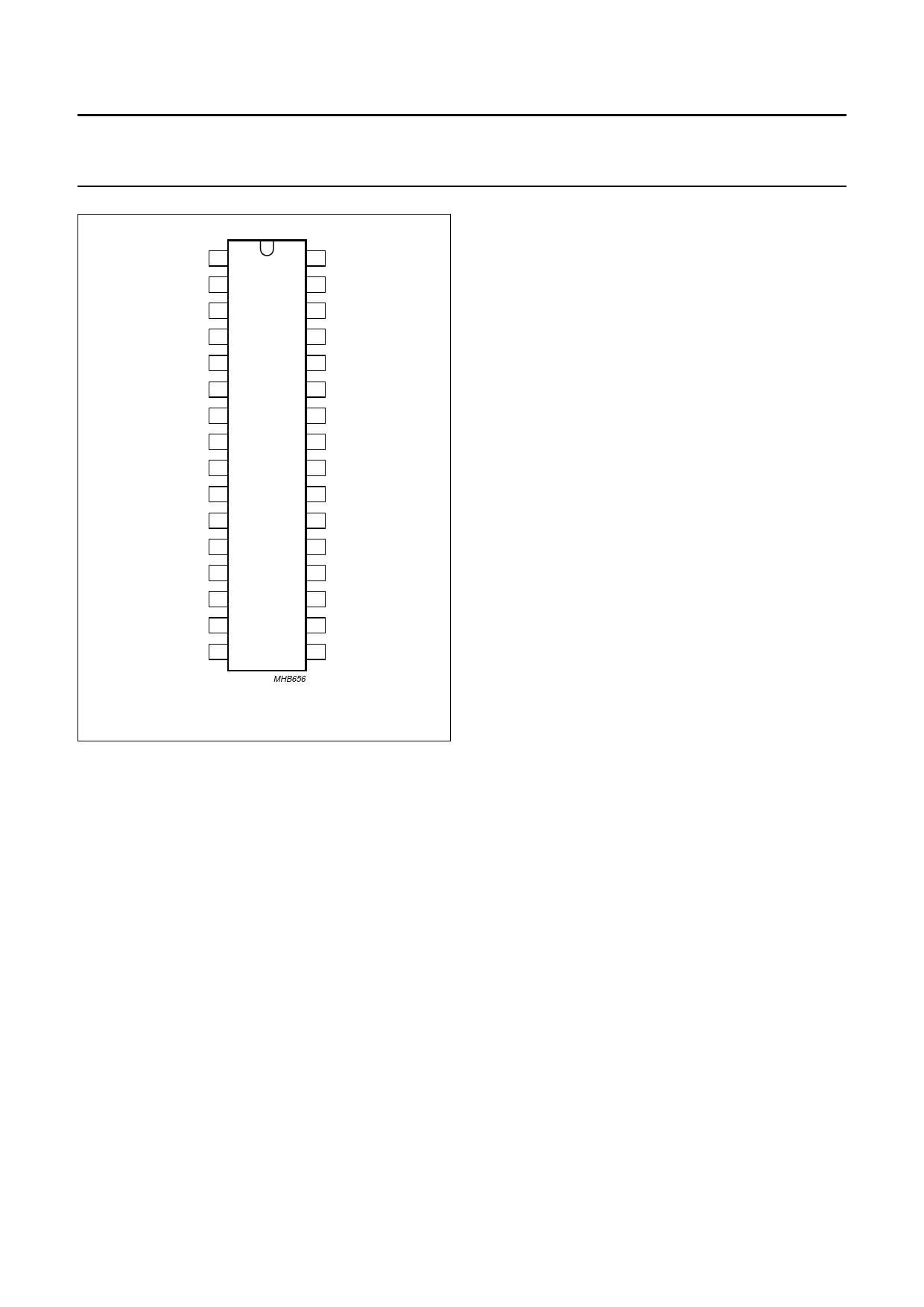

handbook, halfpage

HFLB 1

32 FOCUS

XRAY 2

31 HSMOD

BOP 3

30 HPLL2

BSENS 4

29 HCAP

BIN 5

28 HREF

BDRV 6

27 HBUF

PGND 7

26 HPLL1

HDRV 8

25 SGND

TDA4857PS

XSEL 9

24 VCAP

VCC 10

EWDRV 11

23 VREF

22 VAGC

VOUT2 12

21 VSMOD

VOUT1 13

20 ASCOR

VSYNC 14

19 SDA

HSYNC 15

18 SCL

CLBL 16

17 HUNLOCK

MHB656

Fig.2 Pin configuration.

FUNCTIONAL DESCRIPTION

Horizontal sync separator and polarity correction

HSYNC (pin 15) is the input for horizontal synchronization

signals, which can be DC-coupled TTL signals (horizontal

or composite sync) and AC-coupled negative-going video

sync signals. Video syncs are clamped to 1.28 V and

sliced at 1.4 V. This results in a fixed absolute slicing level

of 120 mV related to top sync.

For DC-coupled TTL signals the input clamping current is

limited. The slicing level for TTL signals is 1.4 V.

The separated sync signal (either video or TTL) is

integrated on an internal capacitor to detect and normalize

the sync polarity.

Normalized horizontal sync pulses are used as input

signals for the vertical sync integrator, the PLL1 phase

detector and the frequency-locked loop.

Vertical sync integrator

Normalized composite sync signals from HSYNC are

integrated on an internal capacitor in order to extract

vertical sync pulses. The integration time is dependent on

the horizontal oscillator reference current at HREF

(pin 28). The integrator output directly triggers the vertical

oscillator.

Vertical sync slicer and polarity correction

Vertical sync signals (TTL) applied to VSYNC (pin 14) are

sliced at 1.4 V. The output signal of the sync slicer is

integrated on an internal capacitor to detect and normalize

the sync polarity. The output signals of vertical sync

integrator and sync normalizer are disjuncted before they

are fed to the vertical oscillator.

Video clamping/vertical blanking generator

The video clamping/vertical blanking signal at CLBL

(pin 16) is a two-level sandcastle pulse which is especially

suitable for video ICs such as the TDA488x family, but also

for direct applications in video output stages.

The upper level is the video clamping pulse, which is

triggered by the horizontal sync pulse. Either the leading or

trailing edge can be selected by setting control bit CLAMP

via the I2C-bus. The width of the video clamping pulse is

determined by an internal single-shot multivibrator.

The lower level of the sandcastle pulse is the vertical

blanking pulse, which is derived directly from the internal

oscillator waveform. It is started by the vertical sync and

stopped with the start of the vertical scan. This results in

optimum vertical blanking. Two different vertical blanking

times are accessible, by control bit VBLK, via the I2C-bus.

Blanking will be activated continuously if one of the

following conditions is true:

Soft start of horizontal and B+ drive [voltage at HPLL2

(pin 30) pulled down externally or by the I2C-bus]

PLL1 is unlocked while frequency-locked loop is in

search mode or if horizontal sync pulses are absent

No horizontal flyback pulses at HFLB (pin 1)

X-ray protection is activated

Supply voltage at VCC (pin 10) is low (see Fig.23).

Horizontal unlock blanking can be switched off, by control

bit BLKDIS, via the I2C-bus while vertical blanking and

protection blanking is maintained.

2000 Jan 31

6