NVD0.1CKK-M6 데이터 시트보기 (PDF) - Power-One Inc.

부품명

상세내역

제조사

NVD0.1CKK-M6 Datasheet PDF : 11 Pages

| |||

NV Series: 4 - 6W DC/DC Converters

9-36V, 18-36V, 36-72V & 16-75V Inputs

3.3V, 5.0V, 12V, 15V, ±5.0V, ±12V, ±15V & ±24V Outputs

Product Specifications

Oct 2001

Surface Mount Assembly

Soldering:

The following instructions must be observed when

soldering the unit. Failure to observe these

instructions may result in failure or significant

degradation of the module performance. Power-

One will not honor any warranty claims arising

from failure to observe these instructions.

This product is approved for forced convection

reflow soldering only.

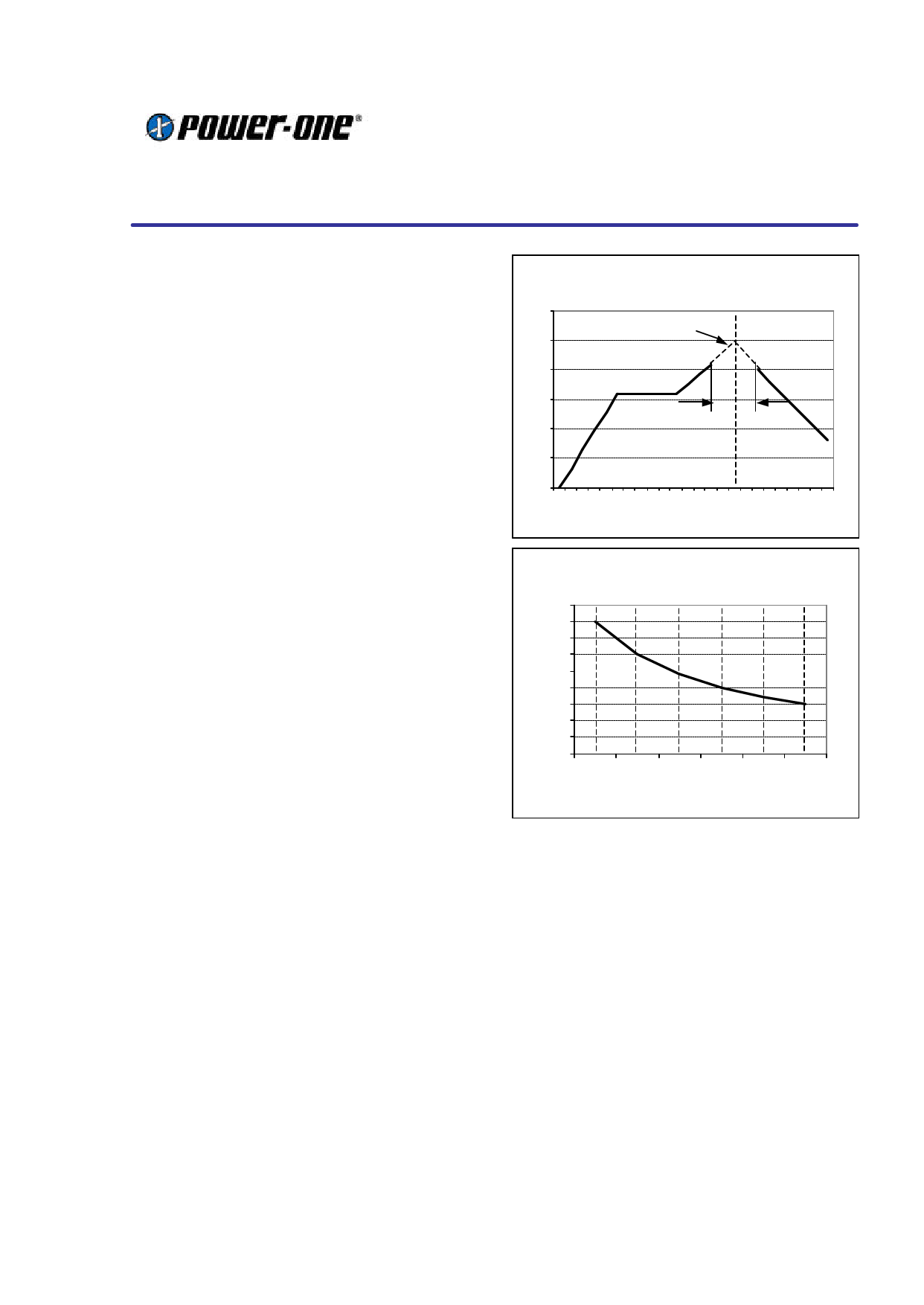

The curves below define the maximum peak

reflow temperature permissible measured on

Pins 1 and 10 of the converter.

The lead-frame is constructed for a high

temperature glass filled, UL94V0 flame retardant,

diallyl ortho-phthalate moulding com pound

commonly used for packaging of electronics

components. It has passed NASA outgassing

tests and is certified to MIL-M-14. The coefficient

of thermal expansion is equivalent to FR4.

The gull wing leads are formed to ensure optimal

solder joint strength and structure. Furthermore

they facilitate optical inspection (manual or

automatic). The leads are formed from a 97% Cu

alloy plated with Cu and Sn 90. This material is

commonly used in the manufacture of integrated

circuits. It has good corrosion resistance and

exhibits the nobility inherent to all high copper

alloys. Unlike brasses, this material is essentially

immune to stress corrosion cracking. It also

exhibits excellent solderability. It is readily

wetted by solders and performs well in standard

solderability tests. (Dip of Class II or better).

The product is manufactured with a patented

process, which is fully automated, and ‘in-line’.

This ensures that there is no contamination or

mechanical stress on the lead-frame so that the

co planarity and solderability are maintained.

The product is shipped in JEDEC trays to

guarantee preservation of the co-planarity and

enable fully automated assembly in the final

application.

.

Max. temp. on pins 1 and 10 during reflow

soldering (deg C)

300

Peak Temperature

(See fig below)

250

200

150

tp

100

50

0

190 – 450 s

Time (s)

Restriction curve above 215ºC

Peak temp. at pins 1 and 10 (ºC)

245

240

235

230

225

220

215

210

205

200

10 20 30 40 50 60

tp (s)

Pick & Place Assembly:

The product is designed with a large flat area in

the center of the top surface to serve as a pick up

point for automated vacuum pick and place

equipment. The ‘open board’ construction of the

unit ensures that weight is kept to a minimum.

However due to the relatively large size of the

component, a large nozzle (> 2.0mm, depending

on vacuum pressure) is recommended for picking

and placing.

The unit may also be automatically handled using

‘odd-form’ placement equipment, with mechanical

grippers. For this type of equipment the end

edges of the device, which have no leads and

also feature the greatest dimensional accuracy,

should be used as pick-up points.

18-Oct-01

Rev 1.0

www.power-one.com

Page 8 of 11