20020000-C022B01LF 데이터 시트보기 (PDF) - Unspecified

부품명

상세내역

제조사

20020000-C022B01LF Datasheet PDF : 9 Pages

| |||

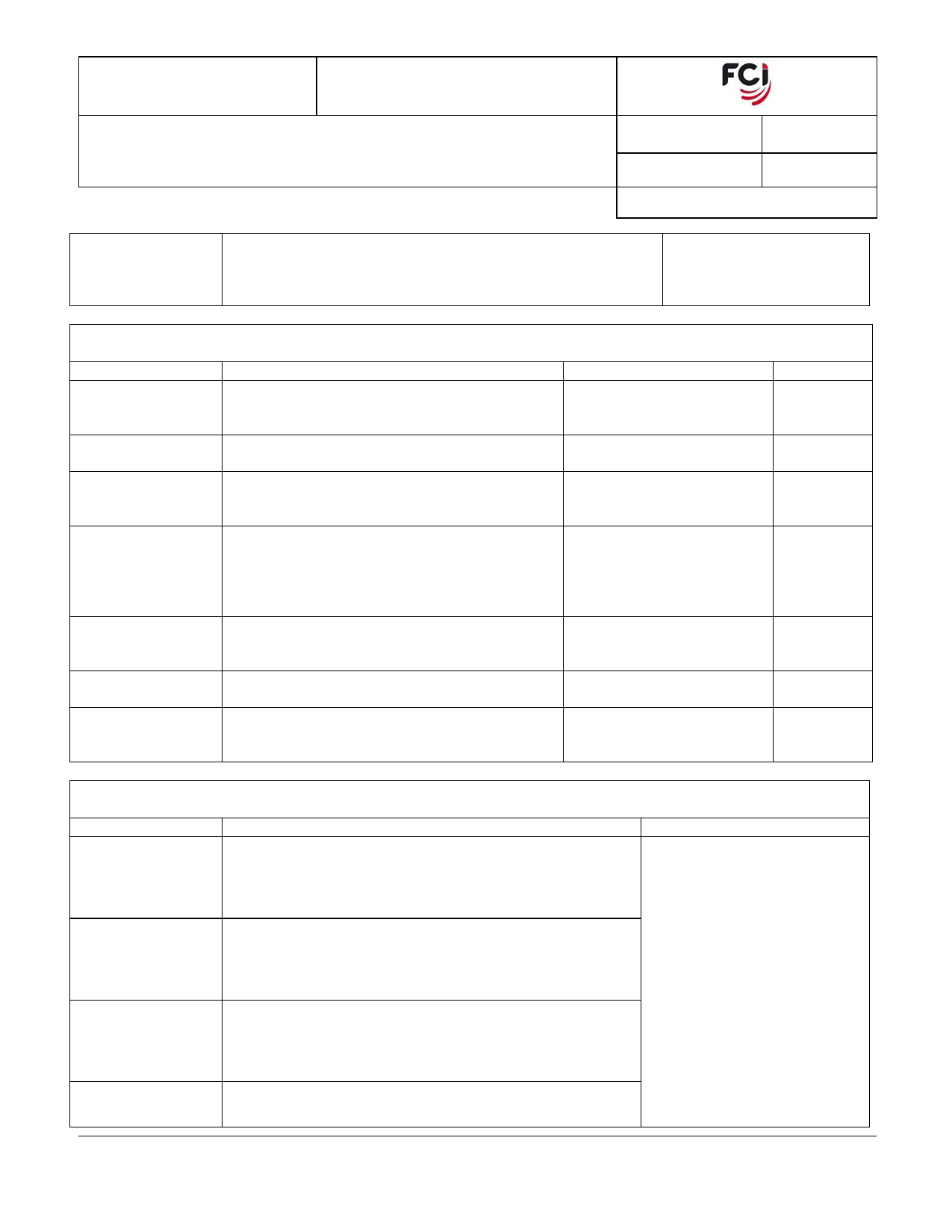

NUMBER

GS-12-625

TYPE

Product Specification

TITLE

Terminal block- Plug and Socket, Fixed Plug

PAGE

REVISION

4 of 8

D

AUTHORIZED BY

Jason Hsu

DATE

Nov. 11th, 2009

CLASSIFICATION

Unrestricted

3.5.1.5

Temperature rise

VS current

UL 1059

Measurements are made when the specimen had reached

thermal equilibrium at the rated current specified on

individual drawing.

+30 ℃ Maximum

3.5.2

MECHANICAL REQUIREMENTS

DESCRIPTION

TEST CONDITION

3.5.2.1

Mate connector and measure the force

Mating force

required.

REQUIREMENT

5.5N Maximum.

(Per mating pole.)

Applicable

Plug/socket

3.5.2.2

Unmating force

3.5.2.3

Durability

(mate/unmate)

3.5.2.4

Wire Pull Strength

3.5.2.5

Torque

3.5.2.6

Pin Retention

3.5.2.7

Solder ability

Unmate connector and measure the force

required.

After durability cycles, low level contact

resistance shall be less than 20millionohm.

IEC 60998-2-1 paragraph 10.105,

Subject connector to a pull force for 1 minute

in the axis of tapping connector.

Connector shall not slip out of the connecting

device.

UL1059

Apply the rated torque (refer to drawings) for

wire attachment.

Force required to unload pin from the housing

in the direction of plug entry.

Soldering time 5 second. (flux is applied)

Soldering temperature: 250±10℃

1.0N Minimum.

(Per unmating pole.)

200 Cycles

Plug/socket

Plug/socket

10AWG: Min 80N

12AWG: Min 60N

16AWG: Min 30N

24AWG: Min 13N

Plug/Fixed

plug

No visible crack

Plug/Fixed

Plug

Min 20N.

Socket

95% min of solder area and Fixed

the plastics have not been plug/Socket

melted

3.5.3

ENVIRONMENT REQUIREMENTS

DESCRIPTION

TEST CONDITION

REQUIREMENT

3.5.3.1

Heat Resistance

3.5.3.2

Cold resistance

IEC 60998-2-1, paragraph 12.1

Subject specimens to 115±2℃ for 168 hours and shall be

left alone for 1 to 2 hours in a room ambient for next

examination/testing.

IEC 60998-2-1, paragraph 12.1

Subject specimens to -40±2℃ for 168 hours and shall be

No cracks visible.

No material becomes sticky.

No material becomes greasy.

Specimen shall not undergo

any change impairing their

further use.

left alone for 1 to 2 hours in a room ambient for next

examination/testing..

3.5.3.3

Humidity

IEC 60998-1, paragraph 12.2.

Subject specimens to 30±2℃, relative humidity 91%~95%

for 48 hours and shall be left alone for 1 to 2 hours in a

room ambient for next examination/testing...

3.5.3.4

Salt Spray

EIA-364-26B, condition A

Salt concentration: 5%, temperature 32±2℃, 48hours.

PDS: Rev :E

STATUS:Released

Printed: Mar 05, 2012

This document is the property of and embodies CONFIDENTIAL and PROPRIETARY information of FCI. No part of the information shown on the document may be used in any way or

disclosed to others without the written consent of FCI. Copyright FCI.

Form E-3005

Rev F

GS-01-001